Semi High Speed Steel Rolls.

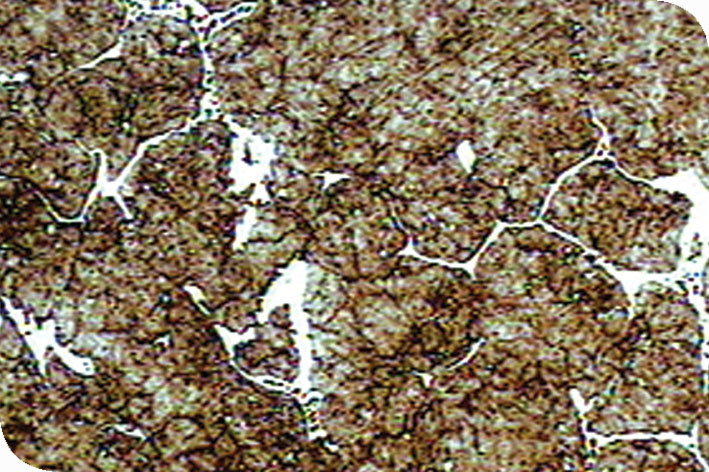

The microstructure consists of tempered martensite Chromium carbides and dispersion of fine secondary carbides.

These rolls have excellent thermal shock and wear resistance.

Semi High Speed Steel rolls mostly used for roughing and F1-F4 stands of Hot Strip Mills and finishing stands of small section mills and universal rings of section mills.

|

|

|

SSH72C -Tempered Martensite with M7C3 and M23C6 Carbides.(x100) |

SSH72C -Tempered Martensite with M7C3 and M23C6 Carbides.(x400) |

Chemical Composition and Mechanical Properties of Semi High Speed Steel Rolls

|

Roll Grade |

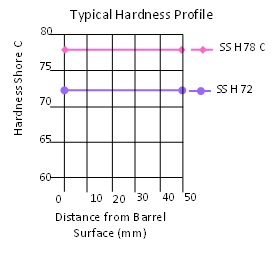

Barrels Hardness (ShC) |

C (%) |

Si (%) |

Mn (%) |

Cr (%) |

Ni (%) |

Mo (%) |

W (%) |

V+Nb (%) |

Composition, Hardness and Properties of Core Material |

|

SS H 72 C |

72 |

0.3-1.0 |

0.4-1.0 |

0.3-1.0 |

0.5-8.0 |

0.2-1.2 |

2.0-4.0 |

0.8-1.5 |

0.2-1 |

See core Material Info in link1 |

|

SS H 74 C |

74 |

0.3-1.0 |

0.4-1.0 |

0.3-1.0 |

0.5-8.0 |

0.2-1.2 |

2.0-4.0 |

0.8-1.5 |

0.2-1 |

See core Material Info in link1 |

|

SS H 76 C |

76 |

0.3-1.0 |

0.4-1.0 |

0.3-1.0 |

0.5-8.0 |

0.2-1.2 |

2.0-4.0 |

0.8-1.5 |

0.2-1 |

See core Material Info in link1 |

|

SS H 78 C |

78 |

0.3-1.0 |

0.4-1.0 |

0.3-1.0 |

0.5-8.0 |

0.2-1.2 |

2.0-4.0 |

0.8-1.5 |

0.2-1 |

See core Material Info in link1 |

Note: On request, other roll grades not specified in the table can be produced.