Production method: static and centrifugal casting

Maximum weight: no limit

Maximum diameter: no limit

Maximum barrel length: no limit

Grades:

Clear Chilled Cast Iron

Pearlitic Cast Iron

For more information, please refer to the customer technical support section in the grades section.

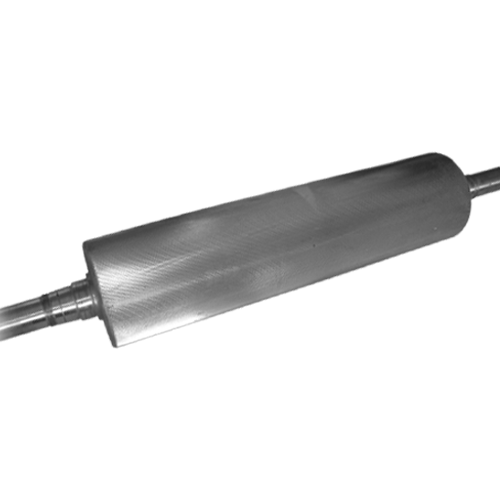

By relying on the latest technology from around the world and utilizing existing facilities, Chodan Sazan Manufacturing Company produces rolls that meet the highest global standards for functionality and durability. These rolls are designed for the flour production industry and other food-related industries, and are capable of competing with rolls made in European countries.

For crushing rolls, the outer layer is made of clear chill cast iron, while the inner layer is made of gray cast iron. The barrel length of these rolls ranges from 800 to 1500 mm. additionally; we accept custom orders for rolls with other dimensions to meet specific customer needs.

| Chemical Composition and Mechanical Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Roll Grade | Barreis Hardness(HB) | C | Si | Mn | Cr | Ni | Mo | ||||||

| CC64C | 440-490 | 3.0 | 3.6 | 0.3 | 0.7 | 0.1 | 0.5 | 0.3 | 1.4 | 0.2 | 0.8 | 0.1 | 0.3 |

| CC70C | 490-530 | 3.0 | 3.8 | 0.3 | 0.7 | 0.1 | 1.5 | 0.3 | 1.4 | 0.4 | 1.0 | 0.1 | 0.3 |

| CCNIH76C | 530-570 | 3.2 | 3.8 | 0.3 | 0.7 | 0.3 | 0.8 | 0.8 | 1.5 | 2.0 | 3.5 | 0.2 | 0.6 |

| CCNIH80C | 570-630 | 3.2 | 3.8 | 0.3 | 0.7 | 0.3 | 0.8 | 0.8 | 1.5 | 2.0 | 3.5 | 0.2 | 0.6 |

| Common Dimension | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length(mm) | Diameter(mm) | Weight(Kg) | Minimum Working Layer | Max Working Layer | |||||||||

| 800+_0.1 | 250+_0.1 | 300 | 20mm | Customer’s Choice | |||||||||

| 1000+_0.1 | 250+_0.1 | 370 | 20mm | Customer’s Choice | |||||||||

| 1250+_0.1 | 250+_0.1 | 470 | 20mm | Customer’s Choice | |||||||||

| 1500+_0.1 | 250+_0.1 | 650 | 20mm | Customer’s Choice | |||||||||

*Description: It is possible to produce other dimensions according to the customer’s request plan.

| Journal Properties | ||||||

|---|---|---|---|---|---|---|

| Core Grade | UTS(N/mm*) | Elongation(%) | Bending Strength(N/mm*) | Youngs Modulus E(KN/mm*) | ||

| CK45 | 590-740 | 18 | 1000 | 1200 | 205 | 215 |

Flaker rolls andoil extraction rolls

Rolls are crucial equipment in the oilseed oil extraction process, and having rolls with high hardness and resistance is of utmost importance to prevent damage from impurities.

Oil extraction rolls are produced using static and centrifugal casting methods. The outer layer is made of clear chill cast iron, while the inner layer is made of gray cast iron. The arms are made of forged steel and are connected to the roller, taking into consideration their intended use. To eliminate machine vibrations, all rolls undergo a balancing process, and anti-wear rings can be installed on each side of the roller upon customer request.

The final surface finishing of the roller is carried out according to customer specifications.

| Chemical Composition and Mechanical Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Roll Grade | Barrel Hardness(HB) | C | Si | Mn | Cr | Ni | Mo | ||||||

| CC70C | 490-530 | 3.0 | 3.8 | 0.3 | 0.7 | 0.1 | 0.5 | 0.3 | 1.4 | 0.4 | 1.0 | 0.1 | 0.3 |

——————-

| Common Dimensions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length(mm) | Diameter(mm) | Weight(Kg) | |||||||||||

| 1600+_0.1 | 800+_0.1 | 300 | |||||||||||

| 1300+_0.1 | 800+_0.1 | 370 | |||||||||||

* Description: It is possible to produce other dimensions according to the customer’s request.

| Journal Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Core Grade | UTS(N/mm*) | Elongation(%) | Bending Strength(N/mm*) | Youngs Modulus E(KN/mm)* | |||||||||

| CK45 | 590-740 | 18 | 1000 | 1200 | 205 | 215 | |||||||