Casting Systems

We manufacture both single and double poured rolls. Casting is carried out in both statically and centrifugally.

Molding

Sands and other additives are subjected to strict quality control throughout the molding process.

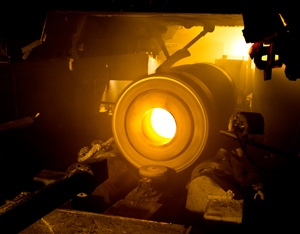

Centrifugal Casting

Horizontal and vertical centrifugal casting machines are used for casting double poured rolls and sleeves.

The core is produced in high quality ductile iron while the shell is an alloyed iron or special steels ensuring low wear and more uniform hardness.

Centrifugal Casting Equipment

Three horizontal spin casting machines are used for rolls and sleeves of up to 3 tons, 250~1100 mm barrel diameter and up to 1200 mm barrel length.

Two big horizontal spin casting machine is used for rolls of up to 40 tons, 550~1400 mm barrel diameter, and 6000 mm barrel length.

One vertical spin casting machine is used for sleeves up to 8 tons and 1400 mm in diameter.

Static Casting

The static casting method is used for single poured and double poured (over flow and slide gate system) rolls for all weight ranges.