Graphitic Steels are high carbon containing hypereutectoid Steels. They combine high strength with good wear resistance against

fire cracking.

They are normalized and stress relieved for better mechanical properties.

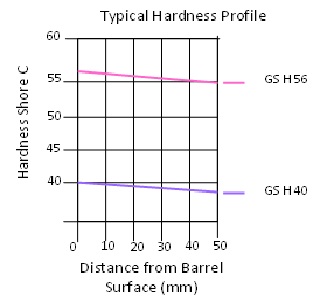

These rolls have a negligible hardness drop.

|

|

|

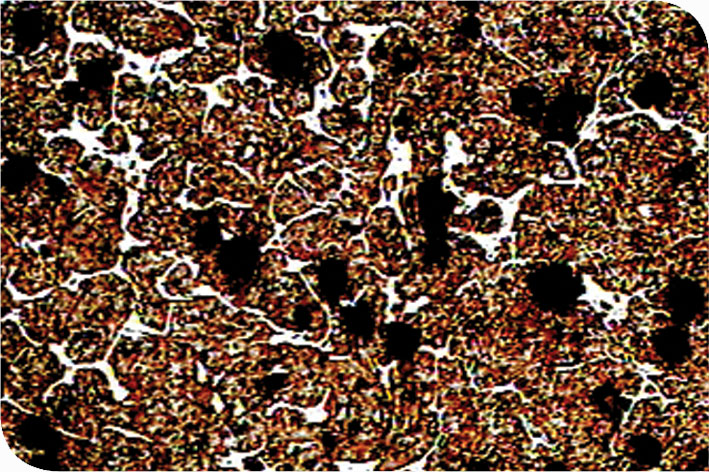

GS H50-Pearlitic matrix with and Graphites and Secondary Carbide(x100) |

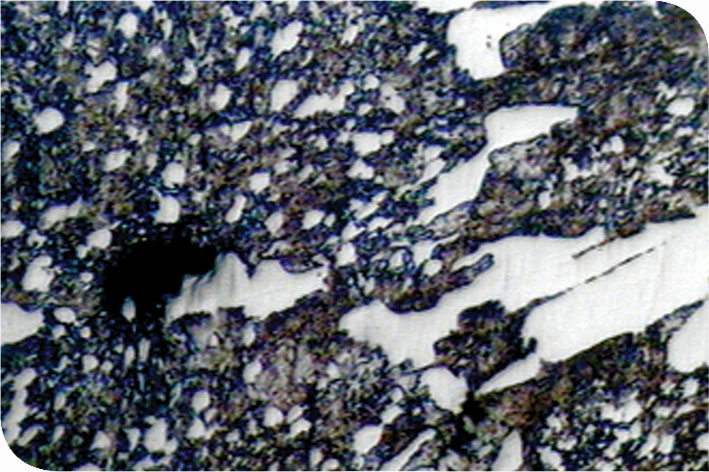

GS H50-Pearlitic matrix with dispersed Secondary Carbide(x400) |

Chemical Composition and Mechanical Properties for Graphite Steel Rolls

| Roll Grade | Barrels Hardness (ShC) | C (%) | Si (%) | Mn (%) | Cr (%) | Ni (%) | Mo (%) | Tensile Strength (N/mm2) | Bending Strength (N/mm2) |

| GSH40 | 40 | 1.5-2.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.2 | 0.5-2.0 | 0.2-0.8 | 500-750 | 700-1100 |

| GSH44 | 44 | 1.5-2.5 | 0.5-1.5 | 0.5-1.5 | 1.0-1.5 | 0.5-2.0 | 0.2-0.8 | 500-750 | 700-1100 |

| GSH48 | 48 | 1.5-2.5 | 0.5-1.5 | 0.5-1.5 | 1.0-1.5 | 0.8-2.5 | 0.2-0.8 | 550-750 | 800-1100 |

| GSH52 | 52 | 1.5-2.5 | 0.5-1.5 | 0.5-1.5 | 1.2-1.8 | 1.5-2.5 | 0.2-0.8 | 550-800 | 900-1200 |

| GSH56 | 56 | 1.5-2.5 | 0.5-1.5 | 0.5-1.5 | 1.2-1.8 | 1.5-2.5 | 0.2-0.8 | 550-800 | 900-1200 |

Note: Other roll grades not specified in the table can be produced on request.