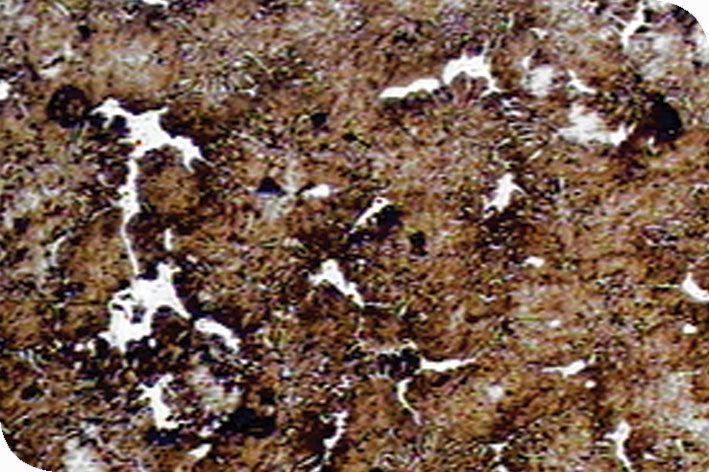

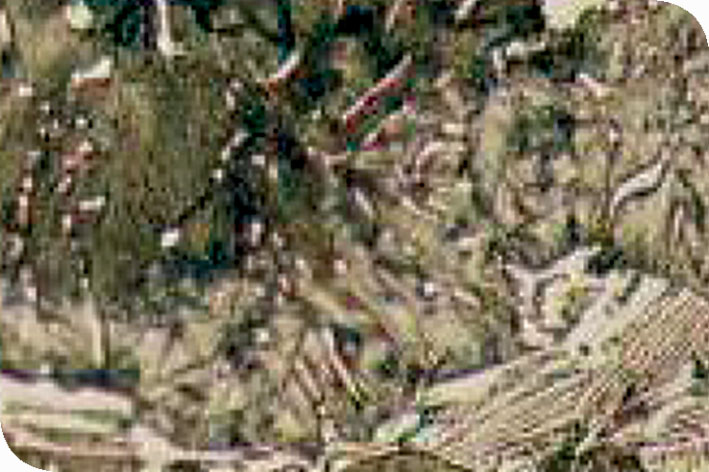

High speed steel alloys are high carbon alloy steel containing Cr, Mo, W, Co, V and Nb. Micro structure consist of complex carbides embedded in a tempered martensite.

These rolls and sleeves are doubled poured which is combined extra wear resistance of the shell together with toughness of the core.

High Speed Steel Roll grades are widely used as Hot Strip Mills F1-F4 work rolls, pre-finishing and finishing stands of wire bar and rebar mills.

|

|

|

HSH 76C -Tempered Martensite with M7C3 and MC Carbides(x100 |

HSH 76C-Tempered Martensite with M7C3 and MC Carbides(x400) |

Chemical Composition and Mechanical Properties of High Speed Steel Rolls and Rings

|

Roll Grade |

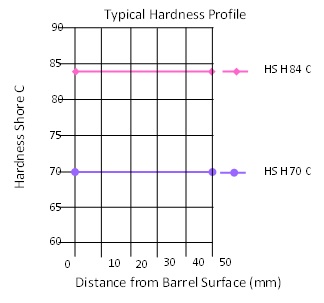

Barrels Hardness (ShC) |

C (%) |

Si (%) |

Mn (%) |

Cr (%) |

Ni (%) |

Mo (%) |

W (%) |

V+Nb (%) |

Composition, Hardness and Mechanical Properties of Core Material |

|

|

|

HS H 70 C |

70 |

1.6-2.2 |

0.3-0.6 |

0.6-1.2 |

4.0-6.0 |

1.0-2.5 |

2.0-4.0 |

1.5-4.0 |

3.0-6.0 |

See core Material Info in link1 |

||

|

HS H 74 C |

74 |

1.6-2.2 |

0.3-0.6 |

0.6-1.2 |

4.0-6.0 |

1.0-2.5 |

2.0-4.0 |

1.5-4.0 |

3.0-6.0 |

See core Material Info in link1 |

||

|

HS H 76 C |

76 |

1.6-2.2 |

0.3-0.6 |

0.6-1.2 |

4.0-6.0 |

1.0-2.5 |

2.0-4.0 |

1.5-4.0 |

3.0-6.0 |

See core Material Info in link1 |

||

|

HS H 80 C |

80 |

1.6-2.2 |

0.3-0.6 |

0.6-1.2 |

4.0-6.0 |

1.0-2.5 |

2.0-4.0 |

1.5-4.0 |

3.0-6.0 |

See core Material Info in link1 |

||

|

HS H 84 C |

84 |

1.6-2.2 |

0.3-0.6 |

0.6-1.2 |

4.0-6.0 |

1.0-2.5 |

2.0-4.0 |

1.5-4.0 |

3.0-6.0 |

See core Material Info in link1 |

||

Note: On request, other roll grades not specified in the table can be produced.