The high Cr content of the shell material and the absence of free graphite characterize these grades. Different types of carbides with high hardness and a tempered

They bring high performance figures in the first finishing stands of Hot Strip Mills, Skin Pass stands and in finishing stands of small sect ion mills.

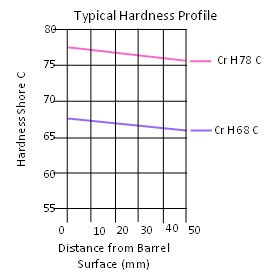

These rolls have hardly any hardness drop in the shell. The core can be made of nodular or lamellar graphite iron. This grade due to lack of graphite in the shell is sensitive to fire cracks and require mills with well designed cooling system.

Enhanced Hi Cr rolls are alloyed additionally with W, V and Nb to increase the hardness of eutectic carbides, hence increasing the performance of the rolls significantly.

|

|

|

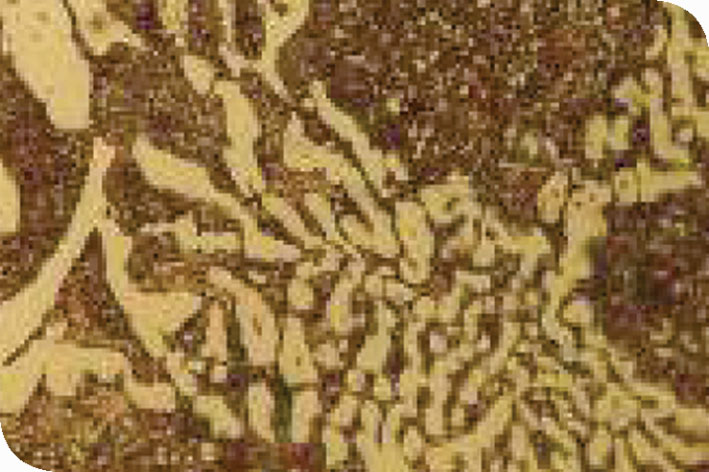

CrH76C-Tempered Martensite with Eutectic and Secondary Carbide(x100) |

CrH76C-Tempered Martensite with Eutectic and Secondary Carbide(x500) |

|

Roll Grade |

Barrels Hardness (ShC) |

C (%) |

Si (%) |

Mn (%) |

Cr (%) |

Ni (%) |

Mo (%) |

V+Nb (%) |

Composition Hardness and Mechanical Properties of Core Material |

|

Cr H 72 C |

72 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

Cr H 76 C |

76 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

Cr H 78 C |

78 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

Cr H 80 C |

80 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

Cr H 84 C |

84 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

CrA H 72 C |

72 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

– |

See core Material Info in link1 |

|

CrA H 76 C |

76 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

0.2-1.5 |

See core Material Info in link1 |

|

CrA H 78 C |

78 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

0.2-1.5 |

See core Material Info in link1 |

|

CrA H 80 C |

80 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

0.2-1.5 |

See core Material Info in link1 |

|

CrA H 84 C |

84 |

2.5-3.2 |

0.3-0.8 |

0.7-1.6 |

16.0-22.0 |

1.0-2.5 |

1.0-2.5 |

0.2-1.5 |

See core Material Info in link1 |

Note: On request, other roll grades not specified in the table can be produced. Cores for compound rolls can be produced on request with Grey, Compact or Nodular cast iron.