Generally, rolls made in this grade are cast steel. In this case homogenous distribution of carbides which is obtain by solidification and appropriately distributed in the matrix

Steel base rolls are particularly suitable for operating under heavy load condition. Good shock resistance and moderate wear properties make these rolls general selection for roughing and intermediate stands.

|

|

|

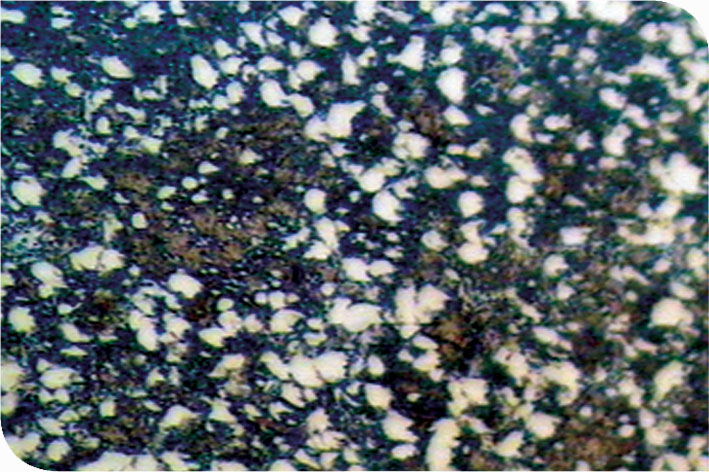

SH58- Pearlitic Matrix with Secondary Carbides (X400) |

SH48-Heat treated Pearlitic Matrix with Secondary Carbides (X100) |

|

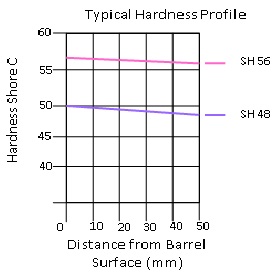

Roll Grade |

Barrels Hardness (ShC) |

C (%) |

Si (%) |

Mn (%) |

Cr (%) |

Ni (%) |

Mo (%) |

Tensile Strength (N/mm2) |

Bending Strength (N/mm2) |

|

SH44 |

44 |

1.4-2.0 |

0.3-0.5 |

0.6-1.2 |

1.2-1.4 |

0.4-1.4 |

0.2-0.5 |

400-600 |

700-1000 |

|

SH48 |

48 |

1.4-2.2 |

0.3-0.5 |

0.7-1.2 |

1.4-1.8 |

0.6-1.4 |

0.2-0.5 |

500-700 |

800-1100 |

|

SH52 |

52 |

1.4-2.2 |

0.3-0.5 |

0.7-1.2 |

1.4-1.8 |

0.6-1.6 |

0.2-0.5 |

500-700 |

800-1100 |

|

SH56 |

56 |

1.4-2.2 |

0.3-0.5 |

0.7-1.4 |

1.4-1.8 |

1.0-1.8 |

0.2-0.5 |

500-700 |

800-1100 |

|

SH48C |

48 |

1.4-2.2 |

0.3-0.5 |

0.6-1.0 |

1.2-1.4 |

0.4-1.6 |

0.2-0.5 |

See core Material Info in link1 |

|

|

SH52C |

52 |

1.4-2.2 |

0.3-0.5 |

0.8-1.2 |

1.4-1.8 |

0.8-1.8 |

0.2-0.5 |

See core Material Info in link1 |

|

|

SH56C |

56 |

1.6-2.2 |

0.3-0.5 |

0.8-1.2 |

1.4-1.8 |

1.0-1.5 |

0.2-0.5 |

See core Material Info in link1 |

|

|

SH62C |

62 |

1.6-2.2 |

0.3-0.5 |

0.8-1.2 |

1.4-1.8 |

1.0-2.0 |

0.2-0.5 |

See core Material Info in link1 |

|

|

SH66C |

66 |

1.6-2.2 |

0.3-0.5 |

0.8-1.2 |

1.4-1.8 |

1.0-2.0 |

0.2-0.5 |

See core Material Info in link1 |

|

Note: Other Steel Grades, not Specified in the table are producible on request.