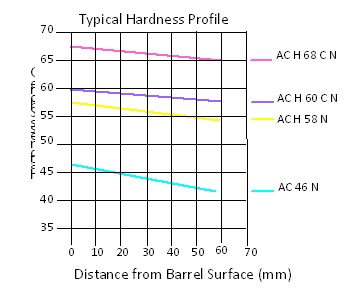

Acicular softer grades have bainitic matrix, and hardest grades have bainitic-martensitic microstructure. Compared with pearlitic rolls, these rolls are higher alloyed and can

Because of their lower thermal conductivity and toughness, acicular rolls have a lower resistance against fire cracking compared to pearlitic rolls. Acicular rolls are stronger and more wear resistant compared to pearlitic rolls of the same hardness. The wear resistance increases with the increasing hardness. Heat treatment improves the resistance to fire cracking.

|

|

|

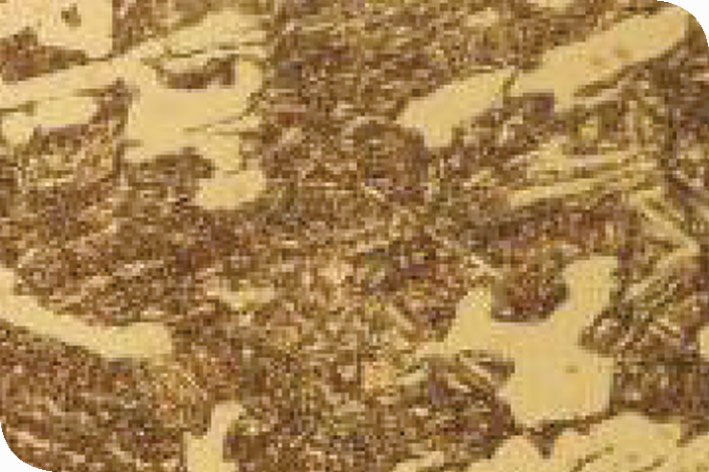

AcH70CN-Acicular Matrix with Carbides and Nodular Graphite(x500) |

AcH62N-Bainitic Matrix with Carbides and Nodular Graphite(x100) |

| Roll Grade | Barrels Hardness (ShC) | C (%) | Si (%) | Mn (%) | Cr (%) | Ni (%) | Mo (%) | Tensile Strength (N/mm2) | Bending Strength (N/mm2) |

| Ac 42N | 42 | 3.2-3.6 | 1.2-2.2 | 0.1-0.4 | 0-0.3 | 2.2-3.5 | 0.2-0.8 | 500-800 | 1100-1300 |

| Ac 46N | 46 | 3.2-3.6 | 1.2-2.2 | 0.1-0.4 | 0-0.3 | 2.2-3.5 | 0.2-0.8 | 500-800 | 1100-1300 |

| Ac 50N | 50 | 3.2-3.6 | 1.2-2.2 | 0.1-0.4 | 0.2-0.5 | 2.2-3.5 | 0.2-0.8 | 400-500 | 1100-1300 |

| Ac H 54 N | 54 | 3.2-3.6 | 1.2-2.0 | 0.1-0.4 | 0.2-0.8 | 2.4-3.8 | 0.2-0.8 | 400-500 | 1100-1300 |

| Ac H 58 N | 58 | 3.2-3.6 | 1.1-1.8 | 0.2-0.6 | 0.2-0.8 | 2.4-3.8 | 0.2-0.8 | 400-500 | 900-1100 |

| Ac H 62 N | 62 | 3.2-3.6 | 1.1-1.8 | 0.2-0.6 | 0.2-0.8 | 2.6-4.2 | 0.2-1 | 400-500 | 900-1100 |

| Ac H 66 N | 66 | 3.2-3.6 | 1.1-1.8 | 0.2-0.8 | 0.3-1.0 | 2.6-4.2 | 0.2-1 | 400-500 | 900-1100 |

| Ac H 68 N | 68 | 3.2-3.6 | 1.1-1.8 | 0.2-0.8 | 0.3-1.0 | 2.6-4.2 | 0.2-1 | 300-450 | 750-950 |

| Ac H 70 N | 70 | 3.2-3.6 | 1.0-1.8 | 0.2-0.8 | 0.4-1.2 | 0.4-1.2 | 0.2-1 | 300-450 | 750-950 |

| Ac H 72 N | 72 | 3.2-3.6 | 1.0-1.8 | 0.2-0.8 | 0.4-1.2 | 2.6-4.2 | 0.2-1 | 300-450 | 750-950 |

| Ac H 60 CN | 60 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 62 CN | 62 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 64 CN | 64 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 66 CN | 66 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 68 CN | 68 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 70 CN | 70 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-0.9 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 72 CN | 72 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-1.1 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 74 CN | 74 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.3-1.1 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

| Ac H 76 CN | 76 | 3.2-3.6 | 1.0-1.8 | 0.2-0.7 | 0.4-1.2 | 2.6-4.2 | 0.2-1 | See core Material Info in link1 | |

Note: On request, other roll grades not specified in the table can be produced. Cores for compound rolls can be produced with Grey, Compact or Nodular cast iron.